Tubular Heating Elements are the most versatile, dependable and rugged of any heat generating device. These qualities make Tubular Heating Elements an ideal heat source for many applications. Tubular Heating Elements are the core of the most common heating solutions found today.

Tubular Heating Elements manufactured by ProTherm are made of the highest quality of materials. This gives you the most dependable heat source for your specific needs. When you have to rely on heat to get the job done, you can rely on ProTherm Tubular Heating Elements to do it right.

Tubular Heating Elements are a mineral insulated, metal-sheathed electric resistance heater. They are sometimes referred to as CalRod® Heaters.

ProTherm Industries offers you the absolute best Tubular Heating Elements available.

With many years of experience designing and applying heating elements, we have mastered both the science and art of Tubular Heating Elements manufacturing. Your ProTherm heater will perform as you expect it to.

Components

ProThermB uses 80-20 ni-chrome wire, “A” grade magnesium oxide, and the highest quality tubing. Filling machines and roll reduction equipment are expertly maintained to manufacturer’s tolerances, and final test equipment is fully calibrated. You can expect high quality from us.

Tubular Heating Elements have 4 basic components:

- Metal Sheath

- Magnesium oxide (MgO)

- Helix resistance coil

- Cold section at each end

Here Is What Makes The ProTherm Tubular Heating Elements Your Obvious Choice!

A variety of sheath materials are available for different application conditions. These take into account corrosion and temperature factors. Let us help you choose the optimum sheath material to ensure the longest possible life for your application. Sheath materials include:

- Steel

- Copper

- Titanium

- Incoloy 800®

- Incoloy 840®

- Inconel 600®

- 304 stainless steel

- 316 stainless steel

Only grade “A”, High Purity, MgO is used in all ProTherm heaters. This material contributes to better heat transfer properties and higher electrical insulation from the sheath. The result is a high quality heater which meets the rigorous demands of Industrial process applications.

The resistance element in all heaters made by ProTherm is a premium grade 80/20 Nickel-Chromium Alloy. this material offers higher temperature capabilities and mechanical strength. As with the MgO insulation, a superiror heater component leads to a superior element.

The heater element requires a cold section at each end to keep the electrical terminals from overheating. A steel pin of the desired length is used for this purpose. It is spot welded to the helix coil element for a secure connection. In the final step of assembly, the pin is exposed at each end of the element and is ready to accept a variety of terminal options.

Features:

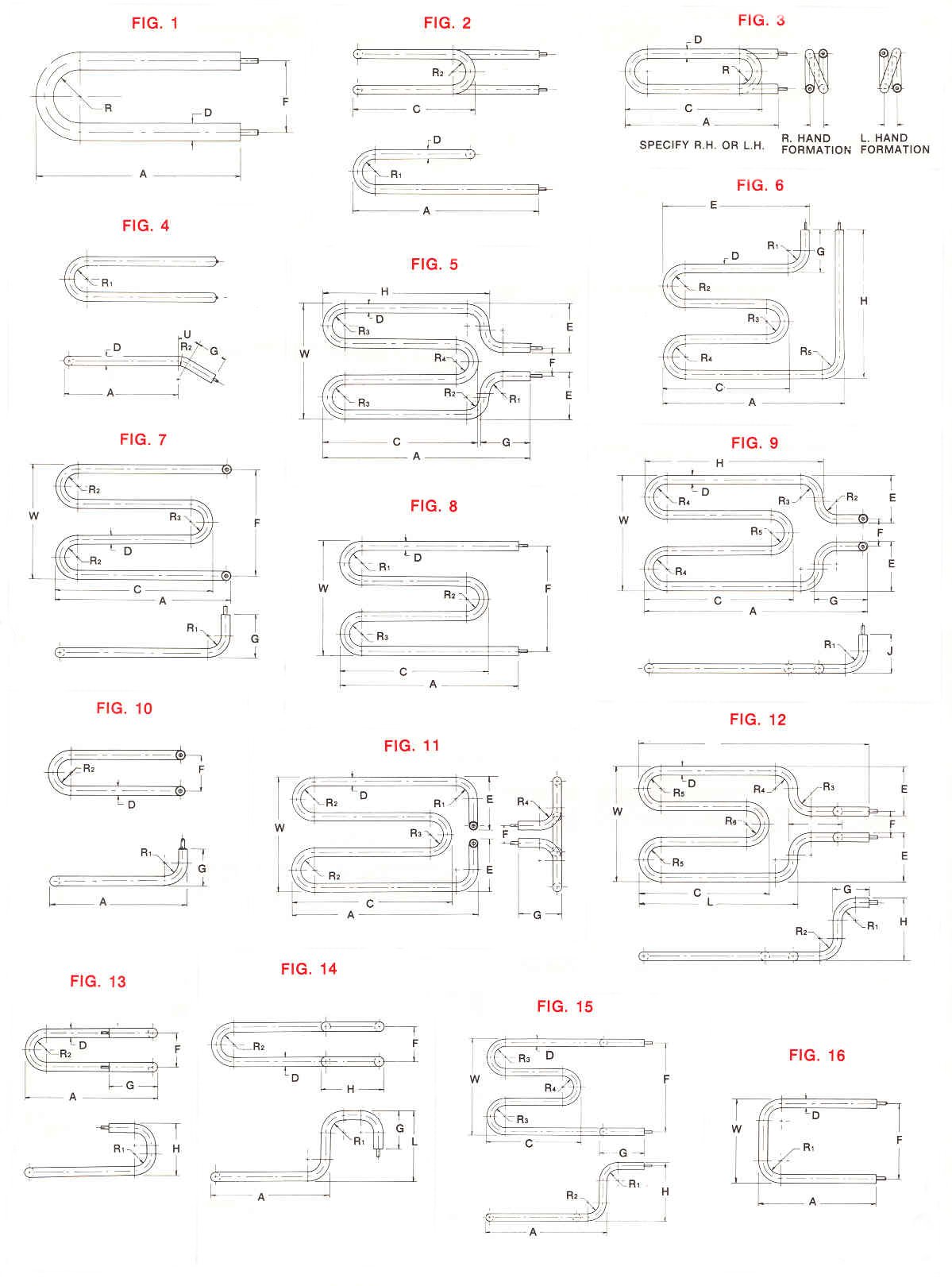

- Elements can be formed into almost any configuration

- Wide variety of wattages and voltages

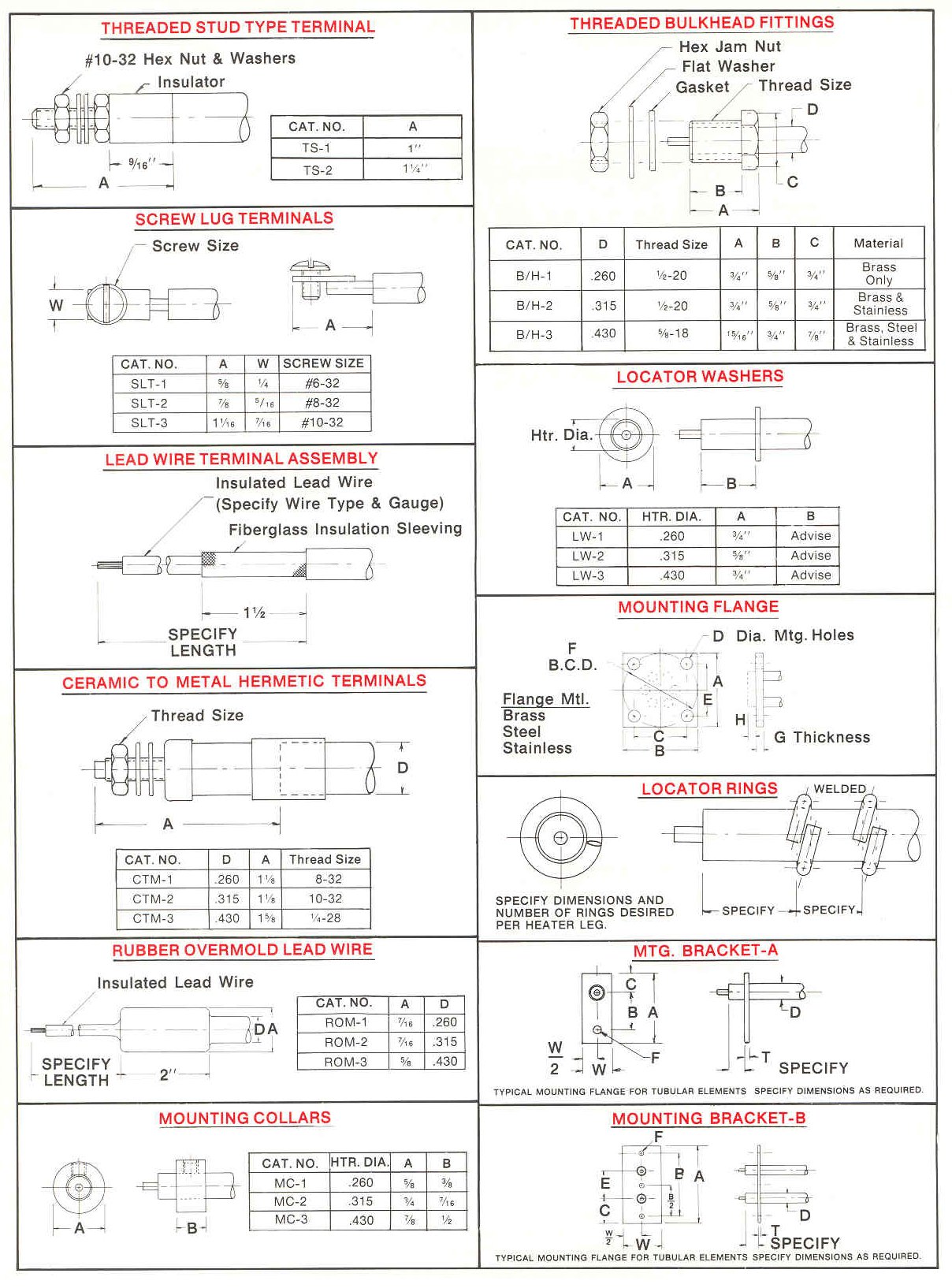

- Wide variety of temination types

- Wide variety of sheath material

- Finned sheath optional

- High purity compacted MgO provides maximum heat conductivity

- Integral cold pins provides optimum in-current carrying capacity.

- Optional end seals

| Sheath Material | Max. Sheath Temp | Watt per Square Inch | Recommended Applications | Available Diameters |

| Copper | 350° F | 50 | Water, Non-Corrosive Liquids | 0.250″, 0.260″, 0.315″, 0.375″, 0.430″, 0.440″, 0.475″, 0.490″, 0.625″ |

| Copper-Clad Steel | 750° F | 20 | Oil immersion, Cast-in, Finned | 0.250″, 0.260″, 0.315″, 0.375″, 0.430″, 0.440″ |

| Stainless Steel | 1200° F | 30 | Corrosive liquids, Food Processing | 0.250″, 0.260″, 0.315″, 0.375″, 0.430″, 0.440″, 0.475″, 0.490″, 0.625″ |

| Incoloy | 1500° F | 40 | Corrosive liquids, air, Clamp-on | 0.250″, 0.260″, 0.315″, 0.375″, 0.430″, 0.440″, 0.475″, 0.490″, 0.625″ |